How heat pump works?

Post by: Omega delta electric

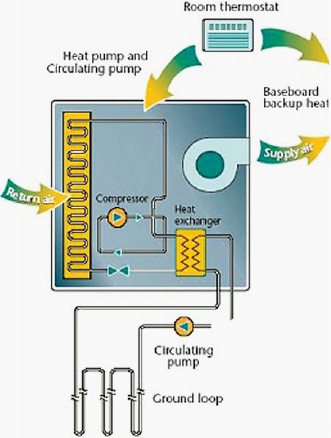

Figure 1: Typical Heat Pump Unit.

The heat pump transfers the heat between the heating/coolingdistribution system and the earth connection. It is the basic building block of the GSHP system. The most common type of heat pump used with GSHP systems is a “water-to-air” unit ranging in size from

3.5 kW to 35 kW of cooling capacity. The water-to-air designation indicates that the fluid carrying heat to and from the earth connection is water or a water/antifreeze mix and that the heat distribution system inside the building relies on hot or cold air.

The heat pump may be an extended range unit, allowing lower entering fluid temperatures in heating mode and higher entering fluid temperatures in cooling mode.

All the components of this type of heat pump are in one enclosure: the compressor, an earth connection-to-refrigerant heat exchanger, controls, and an air distribution system containing the air handler, duct fan, filter, refrigerant-to-air heat exchanger, and condensate removal system for air conditioning. A typical packaged heat pump unit is illustrated inFigure 1.

For residential applications and small commercial systems, a single heat pump unit will suffice. For larger commercial, institutional or industrial systems, multiple heat pump units are typically used in a distributed network connected to a common fluid loop.

The heat pump operates using the same cycle as a refrigerator. The heat pump uses compression and expansion of a refrigerant to drive heat flows between the inside of the building and the earth connection. As per the Second Law of Thermodynamics, heat will flow only from hotter to colder matter, but a heat pump will draw heat from the ground at, say, 5ºC and use it to warm a building to 21ºC. At certain times of the year, the temperature of the ground will be such that heat would flow in the desired direction anyway. The heat pump may still need to operate, however, in order to ensure that the rate of heat flow is sufficient.

This rate is related to the temperature difference between the heat pump and the earth connection: during cooling, the higher the temperature of the building, the better the rate of transfer with the earth connection would be.

In heating mode, the heat pump works as follows: heat from the earth connection arrives at an earth connection-to-refrigerant heat exchanger called the evaporator (see Figure 2). On the other side of the heat exchanger is cold refrigerant in a mostly liquid state. The refrigerant is colder than the temperature of the heat transfer fluid from the earth connection, so heat flows into the refrigerant. This heat causes the liquid refrigerant to evaporate; its temperature does not increase much. This gaseous, low pressure and low temperature refrigerant then passes into an electrically-driven compressor. This raises the refrigerant’s pressure and, as a consequence, its temperature.

The high temperature, high pressure, gaseous output of the compressor is fed into a second heat exchanger, called the condenser. In water-to-air heat pumps, a fan blows air to be heated through this “air coil”. In water-to-water heat pumps, water which will heat the building flows through the condenser. Since the refrigerant is hotter than the air or water, it transfers heat to it. As it loses heat, the refrigerant’s temperature drops somewhat and it condenses.

This high temperature liquid refrigerant then passes through an expansion valve. The valve reduces the pressure of the refrigerant, and as a consequence, its temperature drops significantly. Now, this low temperature liquid flows to the evaporator, and the cycle starts again. In this way, the heat from the water or other heat transfer fluid in the earth connection is transferred to the air or water in the building: hence the name “water-to-air heat pump” or “water-to-water heat pump”.

One significant difference between a ground-source heat pumpand a refrigerator is that the ground-source heat pump is meant to run in both directions. When in cooling mode, the earth connection-to-refrigerant heat exchanger becomes the condenser, and the refrigerant- to-air heat exchanger becomes the evaporator. This is accomplished through a reversing valve inside the heat pump.

A desuperheater, as illustrated inFigure 2, provides domestic hot water when the compressor is operating. The desuperheater is a small auxiliary heat exchanger at the compressor outlet. It transfers excess heat from the compressed gas to water that circulates to a hot water tank.

During the cooling season, when air-conditioning runs frequently, a desuperheater may provide all the hot water needed in a residential application.

figure

2: The Refrigeration Cycle (Heating Mode) of a Typical Packaged Heat Pump Unit.

Some residential heat pumps are designed to provide hot water year round in quantities sufficient to meet a household’s needs.

Figure 1: Typical Heat Pump Unit.

The heat pump transfers the heat between the heating/coolingdistribution system and the earth connection. It is the basic building block of the GSHP system. The most common type of heat pump used with GSHP systems is a “water-to-air” unit ranging in size from

3.5 kW to 35 kW of cooling capacity. The water-to-air designation indicates that the fluid carrying heat to and from the earth connection is water or a water/antifreeze mix and that the heat distribution system inside the building relies on hot or cold air.

The heat pump may be an extended range unit, allowing lower entering fluid temperatures in heating mode and higher entering fluid temperatures in cooling mode.

All the components of this type of heat pump are in one enclosure: the compressor, an earth connection-to-refrigerant heat exchanger, controls, and an air distribution system containing the air handler, duct fan, filter, refrigerant-to-air heat exchanger, and condensate removal system for air conditioning. A typical packaged heat pump unit is illustrated inFigure 1.

For residential applications and small commercial systems, a single heat pump unit will suffice. For larger commercial, institutional or industrial systems, multiple heat pump units are typically used in a distributed network connected to a common fluid loop.

The heat pump operates using the same cycle as a refrigerator. The heat pump uses compression and expansion of a refrigerant to drive heat flows between the inside of the building and the earth connection. As per the Second Law of Thermodynamics, heat will flow only from hotter to colder matter, but a heat pump will draw heat from the ground at, say, 5ºC and use it to warm a building to 21ºC. At certain times of the year, the temperature of the ground will be such that heat would flow in the desired direction anyway. The heat pump may still need to operate, however, in order to ensure that the rate of heat flow is sufficient.

This rate is related to the temperature difference between the heat pump and the earth connection: during cooling, the higher the temperature of the building, the better the rate of transfer with the earth connection would be.

In heating mode, the heat pump works as follows: heat from the earth connection arrives at an earth connection-to-refrigerant heat exchanger called the evaporator (see Figure 2). On the other side of the heat exchanger is cold refrigerant in a mostly liquid state. The refrigerant is colder than the temperature of the heat transfer fluid from the earth connection, so heat flows into the refrigerant. This heat causes the liquid refrigerant to evaporate; its temperature does not increase much. This gaseous, low pressure and low temperature refrigerant then passes into an electrically-driven compressor. This raises the refrigerant’s pressure and, as a consequence, its temperature.

The high temperature, high pressure, gaseous output of the compressor is fed into a second heat exchanger, called the condenser. In water-to-air heat pumps, a fan blows air to be heated through this “air coil”. In water-to-water heat pumps, water which will heat the building flows through the condenser. Since the refrigerant is hotter than the air or water, it transfers heat to it. As it loses heat, the refrigerant’s temperature drops somewhat and it condenses.

This high temperature liquid refrigerant then passes through an expansion valve. The valve reduces the pressure of the refrigerant, and as a consequence, its temperature drops significantly. Now, this low temperature liquid flows to the evaporator, and the cycle starts again. In this way, the heat from the water or other heat transfer fluid in the earth connection is transferred to the air or water in the building: hence the name “water-to-air heat pump” or “water-to-water heat pump”.

One significant difference between a ground-source heat pumpand a refrigerator is that the ground-source heat pump is meant to run in both directions. When in cooling mode, the earth connection-to-refrigerant heat exchanger becomes the condenser, and the refrigerant- to-air heat exchanger becomes the evaporator. This is accomplished through a reversing valve inside the heat pump.

A desuperheater, as illustrated inFigure 2, provides domestic hot water when the compressor is operating. The desuperheater is a small auxiliary heat exchanger at the compressor outlet. It transfers excess heat from the compressed gas to water that circulates to a hot water tank.

During the cooling season, when air-conditioning runs frequently, a desuperheater may provide all the hot water needed in a residential application.

figure

2: The Refrigeration Cycle (Heating Mode) of a Typical Packaged Heat Pump Unit.

Some residential heat pumps are designed to provide hot water year round in quantities sufficient to meet a household’s needs.

Comments